Thierry Graindorge

I look up from my phone at the Saint-Lazare train station in Paris to see a grinning, tan Thierry Graindorge skidding to a stop 10 feet away. He’s gesturing toward me, and to the train about to depart to Lisieux, France. “But my ticket is for the next train,” I say. He raises his hand in protest. Thierry won’t take no for an answer. So I run after him, dragging my suitcase while a shoulder bag thumps my hip, and we board just in time for the two-hour trip to Normandy. There, we’ll visit E. Graindorge’s four cheesemaking facilities, accompanied by Mathilde, Thierry’s 28-year-old daughter.

Once in Lisieux, Thierry plucks the parking ticket off his Audi and we speed off toward Livarot. I laugh nervously as he zooms around a slower vehicle in the narrow lane. It’s clear, however, that Thierry knows these roads like the back of his hand. Soon, congestion gives way to fields, honking Peugeots to balers and tractors, and tourists to the brown-and-white spotted Normande cows with eye markings that give them a bespectacled appearance.

“Zen,” Thierry says, waving at the sea of barley and grass. (In French, grain d’orge translates to “barley seed.”) His bright blue eyes glitter behind round, red glasses. “This is the start of the story.”

In the Beginning

Spotted Normande cows out to pasture

E. Graindorge was founded in these fields. In 1910, a Livarot farmer named Eugène Graindorge—Thierry’s grandfather—began making the raw cow’s milk cheese that dates to the Middle Ages and is named after the town. Traditionally crafted in small vats with milk left over from buttermaking, Livarot is a heady washed-rind cheese wrapped in five bands of rush raffia to help it retain shape during ripening. These strands earned Livarot its nickname, “The Colonel,” as the French military uniform of that rank features the same number of stripes.

Finding success in making and selling Livarot, Eugène became an affineur for other makers. And, like many of his fellow farmers in Normandy, he pressed cider and fermented Calvados from the apples that grow so plentifully in the temperate climate. This was a time of steady growth for E. Graindorge, driven by Livarot. In 1958, Eugène’s son, Bernard, assumed leadership with an eye toward expansion.

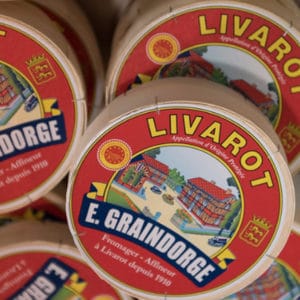

The iconic label of E. Graindorge Livarot

Similar to European stinkers Limburger and Époisses, Livarot was always considered a workingman’s cheese. It requires a leap of faith to get past the first sulfurous whiff to find the sweet, bacony paste within—but because French palates adore complex and assertive cheeses, demand was high. Bernard sourced additional milk from farms in Pays d’Auge nearby, increasing production and eventually introducing his Livarot to Paris. (Today, E. Graindorge is one of a few companies still producing this cheese, which was awarded Protected Designation of Origin, or PDO, status in 1972).

After earning a master’s degree in engineering from Nancy-Université in Lorraine, Thierry Graindorge took the reins from his father in 1970. Since then, he has acquired Fromagerie Domaine de Saint Loup, producer of Camembert de Normandie; the Fromagerie du Plessis facility for making Pont l’Évêque; and Fromagerie du Pays de Bray, which turns out heart-shaped Neufchâtel cheese—all now manufactured under the E. Graindorge label. In 1989, to ensure consistent milk quality, Thierry purchased tanks for farmers who could not afford them so they could store the milk at the proper temperature while waiting for trucks to arrive.

While Thierry is committed to cheesemaking traditions at E. Graindorge, he is always hunting for ways to modernize. “All the time I am working, I am thinking of projects,” he says. “It’s my family, my family business.” Eugène, the farmer, saw an opportunity and ran with it. By sourcing additional milk, Bernard wisely put the business on solid footing. I imagine Thierry wonders how history will remember his expansion into other cheeses.

A Family Business Diversifies

Eugène Graindorge’s 1920 Citroën delivery truck is now on display at Livarot factory

Back on the road, we swing by the Livarot factory. Though rebuilt after a 1999 fire, it looks as it did at the beginning of the 20th century, complete with a maison à colombages façade—plaster over timber frame—and the original 1920 Citroën truck Eugène used to deliver cheese parked near the entrance. Inside, guests may take a self-guided tour through the history of E. Graindorge, observing video footage and photographs from the earliest days onward. While Livarot was the company’s first cheese and flagship product, sales have waned in recent years. Its pasteurized version of Pont l’Évêque, a washed-rind cheese with a sweet and creamy interior, is probably most familiar to US consumers, while its Camembert is known worldwide.

The fluffy white mold we expect to see on a camembert rind dates only 200 years or so. Earlier, wilder iterations might have had a grey cast, perhaps caused by rogue yeast or bacteria. The name “camembert” itself isn’t protected, despite attempts to award it PDO designation—meaning that producers across the world may make the style and call it by that name. However, if the cheese is prepared using defined techniques with raw milk from predominantly Normande cows pastured in the Pays d’Auge—a fertile region encompassing parts of the Calvados and Orne départments—it may be labeled Camembert de Normandie PDO. This is what E. Graindorge makes in the next factory we visit, just over 15 miles to the northwest of Livarot.

E. Graindorge workers hand-ladle curds into forms for Camembert de Normandie

Camembert de Normandie is crafted using time-honored techniques. Cheesemakers must wait until curds coagulate in vats, which are then wheeled into a room warm and heavy with atmospheric moisture. Here, hundreds of molds are set out on long, narrow tables. Skilled workers, each with their own style, ladle curds into the forms with consistent, elegant motions. After a day, staffers apply Penicillium candidum and salt to the cheese surfaces. Then the rounds sit on metal racks in ripening rooms for about 10 days, before being packaged in distinctive wooden boxes. Twenty-one days from cow to cheese, and Camembert de Normandie is on its way.

E. Graindorge also creates Camembert au Calvados—the region’s potent apple brandy is added straight to the vat of curds, resulting in wheels boasting the earthy scent of fermenting apples and the garlicky taste of a well-ripened camembert. One evening during my visit, Thierry opens a bottle of 1930 Calvados made by his grandfather, which we sip alongside nibbles of the boozy round—proof that the cheese really does embody Normandy.

We spend our final day at the E. Graindorge–owned Fromagerie du Pays de Bray in the beautiful town of Neufchâtel-en-Bray, to learn how the cheese of the same name is made. With its bloomy rind and cakelike interior, Neufchâtel Coeur de Bray has an established pedigree. Legend has it that Neufchâtel cheese was made in rounds or random shapes before World War II, Mathilde tells me; during the conflict, French women formed it into hearts in hopes of inspiring peace.

Today Neufchâtel Coeur de Bray remains a small-batch cheese in France and it is sold almost entirely around Valentine’s Day in the US—its sparse showing the rest of the year may explain why the name “Neufchâtel” here is more closely associated with a fresh, cream cheese–like spread. (When I ask how two distinctly different cheeses can have the same name, Mathilde shrugs and reminds me that name protection is extremely difficult and expensive.)

Coming to America

A selection of E. Graindorge cheeses

E. Graindorge has focused on broadening its market to the US for some time. The company is one of a few midsize French cheese producers still owned and operated by its founding family. What’s more, it makes both traditional, raw-milk cheeses for French customers as well as reworked, pasteurized versions of Livarot (wrapped in strands of red food-grade paper instead of customary raffia), Camembert de Normandie, Camembert au Calvados, Pont l’Évêque, and Neufchâtel Coeur de Bray, which meet US safety standards for export. (Smaller cheesemakers simply don’t have the finances or resources to modify versions for the US market.)

In the past decade, family-owned French cheesemaking businesses have consolidated heavily into worldwide powerhouses—think Lactalis and Savencia (née Bongrain). Thierry’s growth plan is similar: acquire other companies to produce new cheeses under his label. Yet for distribution and marketing, he has joined five other like-minded dairies in The French Cheese Club. Members pool resources, coordinate publicity efforts, and cooperate on distribution to the US and beyond, while preserving long-established cheesemaking practices.

During our travels, Thierry points out the high-quality gravure printing plant he purchased recently. He speculates that, perhaps in a few years, Mathilde—who went to school for business, apprenticed as a cheesemaker in Vermont, and is learning the family trade by working in every area of the enterprise—will take over E. Graindorge. Then he’ll focus on printing, or maybe on something else. (The word “entrepreneur” has French origins, after all.)

On our return drive to Lisieux, Thierry talks about how Normandy has changed over the years. (“First it was horses, then cows, now mutton” in the local fields that contribute to the agrarian economy, he says.) But what Thierry cherishes most about the region are the things that stay the same: the history, the peace and quiet, and, most importantly, “the little rains that come every day,” watering the apple trees heavy with plump fruit and driving the agricultural engine.