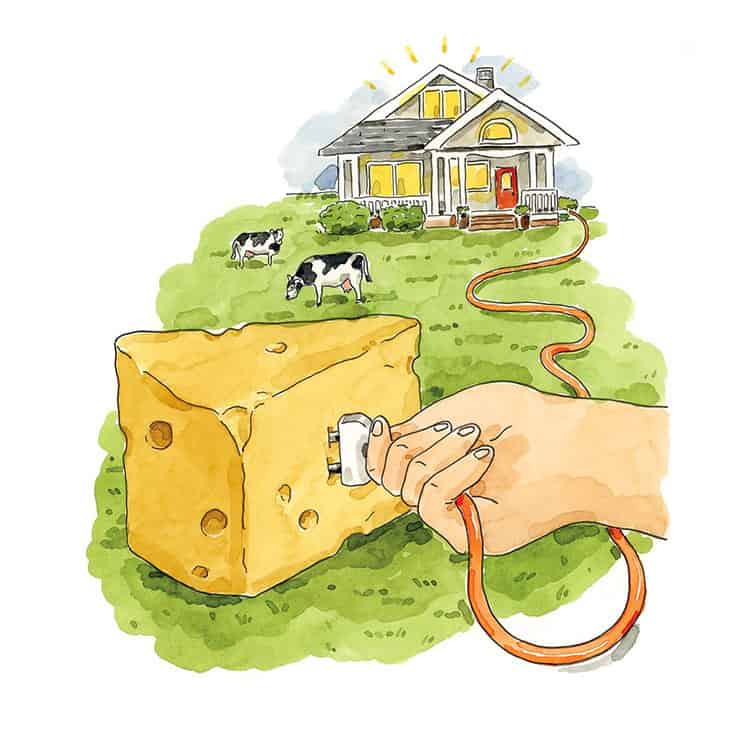

Cheese-to-grid: A surprising configuration of words. It made for an eye-catching headline in 2016 when First Milk, one of the UK’s largest creameries, began converting its waste into renewable energy. Today, that energy alone powers the gas stoves and heaters of some four thousand homes in the surrounding Cumbrian countryside.

How does it work? In a process called anaerobic digestion, microorganisms break down biodegradable material. After cheesemakers at First Milk separate liquid whey from curds, the whey is pumped into a large tank along with other waste fluids (such as the water used to clean cheesemaking equipment). Inside the tank, bacteria are introduced to feed on the mixture’s fats and sugars, metabolizing them into a blend of gases—including methane—that is collectively termed “biogas.”

First Milk’s “digester” facility produces around 35,000 cubic feet of biogas per hour. Some of it fuels an on-site power plant, while the rest is purified (to remove carbon dioxide) before being funneled back into the grid to power local homes and businesses.

This technology isn’t new. Assyrians supposedly used biogas to heat their bathwater as early as 900 B.C. In his travels in China during the 13th century, Marco Polo found covered sewage tanks being used to create power. In the 18th century, Flemish scientist Jan Baptista van Helmont pinpointed how decaying organic matter produces flammable gas. The process isn’t limited to wastewater, either. Many farms today use manure to create fuel; for example, Somerset, UK–based Wyke Farms returns enough biogas from manure to power six thousand area homes.

While sizeable whey digesters exist in a number of European countries (Beaufort cheese, for example, provides the fuel for one of France’s largest digesters), it’s not just the Old World that’s having a gas. The Montchevre facility in Wisconsin—America’s largest goat cheese factory—directs biomethane from its wastewater digester to power residences in its hometown of Belmont. And Richard Koller, owner of Pennsylvania-based Fairview Swiss Cheese, purchased a digester in 2008 after consulting with a biogas engineer who coached his daughter’s basketball team. While he admits that the operating costs have proven more expensive than anticipated, the $2.2 million investment has essentially cut the plant’s electricity bill in half.

Koller has also taken it a step further with the installation of a system that captures the excess heat from the biogas engine and uses it to warm 80,000 gallons of water at a time. That water heater covers 40 percent of his plant’s fuel needs for milk pasteurization, cheesemaking, and cleaning. Because of the massive investments required, technology like this makes most sense for bigger companies. “You do have to be large enough to generate enough waste for fuel,” says Koller, who runs the state’s largest Swiss cheese plant.

Yet growing interest in digesters may result in increased accessibility. “Technology has advanced, [so] smaller, less expensive systems may be feasible,” Koller says. Initiatives like the Renewable Fuel Standard program in the United States are helping offset costs for some, as long as the biogas generates vehicle fuel or renewable natural gas. According to Patrick Serfass, executive director of the American Biogas Council, there’s more interest in this technology than ever before.

“Mostly that’s because of the interest in recycling food waste, keeping nutrients out of our waterways, and helping farms better manage the material they have to handle,” he says. But he adds that the benefits of biogas are still underappreciated by a general public with limited awareness. When it comes to cheese-to-grid technology, knowledge is power, Serfass says: “It’s hard to find someone who knows about biogas systems and doesn’t like them.”

Illustrated by Tom Bingham