Imagine for a second you’re a child and you love firefighters (or astronauts, or dancers, or garbage collectors, or cattle ranchers—your choice, any profession). You might not know it yet, but you want to be one when you grow up. Then imagine you get invited to their place of business for a couple days where they tell you all about their work: the history, the how-to’s, the little secrets. They let you put on the uniform, use the equipment, and get a feel for what it’s like to live that life. For a short time you feel like you’re in a dream; you haven’t blinked in hours and you repeatedly think to yourself, “This is SO cool!”

Now imagine you’re an adult, that profession is cheesemaking, and you have a brilliant photographer friend (Daniel Clapp) who offers to go with you and document the experience.

If your head explodes from all the joy and excitement, you will have imagined something very similar to what I experienced during my recent visit to Parish Hill Creamery.

When Rachel and Peter invited us into their Parish Hill world, we had the opportunity to experience their cheesemaking, quite literally, from farm to table.

Here’s a glimpse of what goes into making Idyll (a part-skim, Gruyère-style cheese) up on Parish Hill:

The process starts with the cows at Elm Lea Farms at the Putney School in Putney, Vt. The herd is a multi-generational mixture of Jersey and Holstein cows, free to roam and graze in the pasture during the summer (when Parish Hill is making their cheese).

Pasture-raised cattle produce milk that give cheese depth, flavor, and variety. Some makers aren’t fond of this, but Peter says, “Why would you want to make cheese that always tastes the same? Where’s the fun in that?”

The fresh milk awaits the daily pickup from Parish Hill in a vat at Elm Lea Farm. The milk travels from the farm to the Parish Hill cheese house in a semi-custom milk truck (born from another of Parish Hill’s partnerships).

The milk is fed from the milk truck into the cheese house vats using gravity and hoses. Inside the cheese house, one end of a hose is fitted with a milk sock (to catch any debris) and the other end is ready to be connected t the milk truck hose through a port near the ceiling.

When Peter yells down from the milk truck into the port (to let Rachel know he’s ready to hook up the vat hose to the truck hose), you feel as though the Cheese God himself is speaking to you.

Once the milk makes it into the house, it sits in a chilled vat overnight to allow the cream to separate from the milk.

The next morning, Peter does a quick calculation to determine the volume of cream to skim off the top in order to achieve the right ratio (of cream to milk) for Idyll.

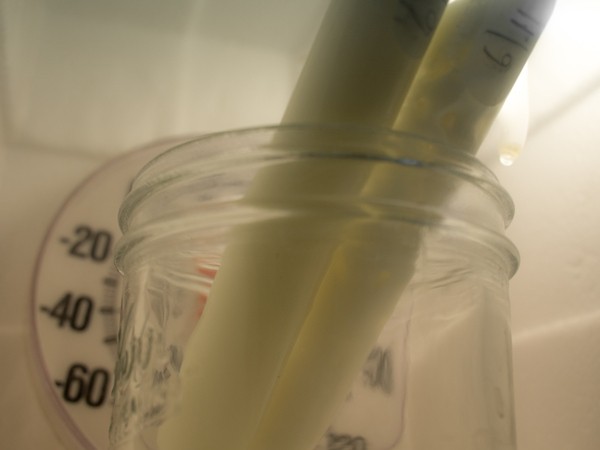

Then, the milk is ready for some testing. (This is where I remember cheese is not actually magic; there is some science too).

And on to the skimming!

After skimming come cultures. Parish Hill proudly makes their own cultures, in the Swiss tradition, using the same milk from a select few cows in the milking herd. The cultures are introduced into the milk as the vat is heated.

Then, it’s rennet time! The rennet is measured and mixed with water before being added into the milk.

After some patience.

And more patience.

A quick texture check.

Flocculation!

Time to (watch the vat) break up the curds.

And a (nearly full-body) curd check.

And some whey draining.

Drain whey, drain…

Oh, what’s that? Curd ready to be shaped?

Carefully into the molds.

At last—cheese!

And, though I would have happily bitten into this wheel of freshly formed cheese, this guy is still a ways from being table-ready. The Idyll journey, in some ways, has just begun.

Come back next week to see the process of making another Parish Hill cheese and what comes after the cheese house for all their curds. (Hint: there’s a cave involved).

All Photos: Daniel J. Clapp