Last September, across town from the Great Hall of Cheese and just up the road past Affineur Alley, a group of cheesemakers began to set up their stalls behind Biodiversity House. They were part of Slow Food’s biennial Cheese event: a four-day weekend in the Piedmontese town of Bra spent tasting, sharing, and learning about cheese.

This particular group of cheesemakers debuted a new section: Piccoli & Naturali (small-scale and natural). They were central to the event’s primary topic of “Natural is Possible,” which Slow Food’s website identified as, “a crucial theme for the future of food, and the next step on our journey from raw milk to natural cheese.”

Piero Sardo, president of the Slow Food Foundation for Biodiversity, explained that while the natural cheese situation in Italy was in relatively good health—the 200-odd Italian Slow Food Presidia all fall within the category—elsewhere it was not the case. Cheese 2019, therefore, was designed with two objectives in mind: to promote those dairies already working in the natural way and to educate the cheese-loving public on what natural cheeses are all about.

“This year’s Cheese,” added Sardo, “was an important step in [the right] direction.”

Starter for Ten

So what exactly is a “natural cheese”? Well, it’s hard to establish a set of category-defining attributes such as flavor, texture, and aroma, especially as the natural cheese umbrella includes cheeses as weird and wonderful asa 100-pound Herzegovinian cheese aged in a sheepskin (so-called “cheese in a sack”) to a fridge mainstay like Parmigiano-Reggiano.

One tenet of this category is the use of raw milk, and a cheesemaking fundamental around which Slow Food has been pushing a program of education for decades. Besides being rich in vitamins, enzymes, and probiotic bacteria, raw milk carries biodiverse microflora that plays a crucial role in developing complexity in a cheese’s aromas and taste (therefore, it’s probably fair to say that natural cheeses tend toward stronger flavors).

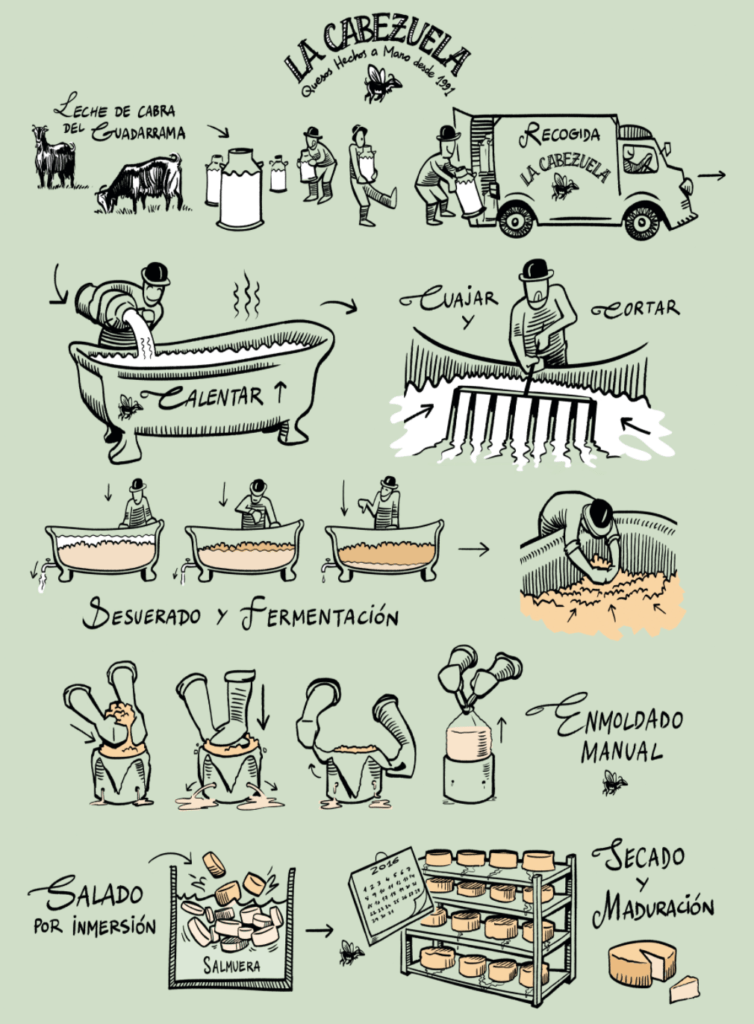

However, Sardo has stated that he sees no logic in working with raw milk if you’re also using commercial starter cultures and rennet—and it was this perspective that had top billing at this year’s Cheese. A starter culture is named for its role in kicking off the cheesemaking process by acidifying the milk—an imperative shift in pH achieved by lactic acid bacteria transforming lactose sugar into lactic acid, which, with the addition of rennet, separates the solid curd from the liquid whey.

As such a crucial part of the process, it’s little wonder that a lucrative industry has grown around lab-developed cultures that can be shipped—frozen or freeze-dried—to anywhere in the world. Its purpose is to replace perceived risky and inefficient natural methods, such as the attractively named “backslopping” technique—the practice of carrying over whey from the last batch of cheese to act as a starter. From a food safety perspective, this carrying over of the whey makes all batches of the cheese as one. If not practiced safely, there’s the chance a pathogen could contaminate the entire stock.

However, David Asher, author of The Art of Natural Cheesemaking and a Slow Food associate, believes the real risk lies with freeze-dried starter cultures.“Freeze-dried microorganisms need time to wake up from their slumbers,” he says. According to Asher, this awakening extends the window for unwanted microorganisms to become involved.

Food safety debates aside, for Sardo and Slow Food the use of non-native lactic bacteria arriving by mail-order can entirely subvert the delicate territorial expression of raw milk. Asher says the commercially produced rennet curdles the milk differently than traditional calf rennet, causing bitter, acrid flavors and delivering a very different curd texture that can lead to a more rubbery cheese.

Such wheels would receive short shrift from Bronwen Percival, buyer for Neal’s Yard Dairy cheesemongers in the UK who was also in Piedmont last September. When asked her definition of natural cheese, her emphasis illuminated another essential part of the category.

“For me, a natural cheese is a cheese that tastes uniquely of the farming system in which it is made, that tastes of the integrity of [that] system,” says Percival. “So not just the use of the native microbes to make the cheese…but actually one that uses rare breeds that are eating a biodiverse landscape of grasses allowing us to really tune into the flavor of a farming system… For me, I’m interested in tasting uniqueness when I buy cheese, not in tasting industrial monoculture.”

The protection and promotion of the use of indigenous and often rare breeds has long been a key part of Slow Food’s Presidia program, as well as the EU’s Protected Designation of Origin (PDO) and Protected Geographical Indication (PGI) scheme. Like Percival, Asher—originally an organic farmer from the Canadian West Coast—sees the use of these native animals (think: Lacaune sheep for Roquefort) alongside non-interventionist farming techniques as essential elements to produce cheese fully expressive of its place of origin.

Lands of Milk and Money

Taken altogether then, natural cheesemaking—unless you’ve been fine-tuning your technique (and business model) for centuries like the Parmigiano-Reggiano producers—makes for a non-commercial proposition. Slow Food’s tagline of “Natural is Possible” begins to sharpen into focus, especially when you look outside of Italy for adherents to natural practices.

“The only country that has a significant presence of natural cheeses [other than Italy] is Portugal,” Sardo says, adding that Switzerland and Germany have little to no production of this category of cheese.

Even France has a very limited number of natural cheeses, although Sardo points to the numerous French goat’s milk cheeses that use lactic coagulation (such as Valençay) instead of rennet as a bulwark against “dramatic homologation.”

Which isn’t to say the French aren’t keen to improve matters. Camembert producers Patrick Mercier and Janine Lelouvier—the only members of Slow Food’s Natural Farmhouse Camembert presidium—are exploring how to eliminate the small amount of non-native starter they currently rely on. Mercier recently told Profession Fromager magazine how it allows him to maintain regular production schedules, which is important for a business with employees to pay. However these are baby steps indeed—Slow Food’s Nicolas Floret, who assists with the Camembert project and others, notes that of the 70,000 tonnes of Camembert produced a year, only about 100 tonnes represents the kind of cheese that Mercier and Lelouvier are producing.

For another eye-watering statistic, we turn to North America, where Asher explains 90 to 95 percent of cheeses are prepared with a lab-produced rennet called fermentation-produced chymosin (FPC) as producers fear that using traditional rennet harvested from calves’ stomachs will deter certain customers. But there are a few beacons of hope for the natural cause stateside: Sister Noella Marcellino, a.k.a. the Cheese Nun, is a long-time practitioner of natural cheesemaking (the FDA’s efforts to swap her “risky” wooden vat for a steel tank backfired when the tank produced the E.coli the vat never had). Asher also singles out the zero-intervention cheesemaking of Jonathan and Nina White at Bobolink Dairy in Milford, New Jersey.

“With their cows outside all winter, no external feeds brought into the system, and only a whey starter saved from one day’s cheese making to the next,” Asher says of the Whites, “they make beautiful, beautiful cheeses that are winning awards internationally.”

The Natural Whey

Back across the Atlantic, another natural cheesemaker—Doetie Trinks—is also collecting awards for her approach to “Doetie’s Geiten” (Doetie’s Goats). Her herd of 75 Toggenburger goats (“Not milk-type goats,” she says, “but strong, sustainable goats”) provides around 50 liters of milk that she uses to make lactic goat’s milk cheeses on her farm in rural Jubbega, about an hour-and-a-half north of Amsterdam.

Trinks is a farmer, but it’s worth noting that she’s also a trained clinical chemical and medical microbiological analyst. Having grown up on a dairy farm, she witnessed the costs and compromises of industrial agriculture and the loss of high-quality milk—it instilled in her a desire to do things differently.

“I consider my cheeses to be natural,” she says. “I do not cool nor heat the milk. The natural microflora remains intact. Cooling kills the lactic acid bacteria…When heated, the milk becomes a breeding ground, and, in addition, heated proteins are difficult for the human body to recognize.”

Trinks produces several lactic goat’s milk cheeses including a Valençay-style called the Swarte Toer (the Black Tower). In the morning, she transfers the milk into a wooden vat and adds a whey starter from her own goat’s milk and rennet derived from the stomachs of her own goats. Come evening, she hand-ladles the curd into cups and lets it drain for two days. Soon the mazey design of Geotrichum candidum, the fungus occurring naturally in her starter, begins inscribing itself on the rinds of her cheese.

When I ask if natural cheesemaking is more intensive than a commercial approach, she replies that her difficulties are more because she’s a one-woman band running a small-scale operation than anything to do with her natural methods. The main difficulty she encounters is legislation in the Netherlands favoring large-scale farming, to the point that small-scale operations pay unrepresentative costs to simply exist. Nevertheless, she balances her farming responsibilities with spreading the word, offering master classes on natural cheesemaking.

And the word is spreading, albeit slowly: Sardo is on a book tour in Italy with his tome on the subject, Formaggi Naturali, while demand for Asher’s Black Sheep School of Cheesemaking continues to take him everywhere from Uruguay to Ukraine—and Bra, of course. It’s along road before the precepts of natural cheese reach the center of the global cheesemaking consciousness. But, as Sardo says, if we don’t start now…

TASTING NOTES

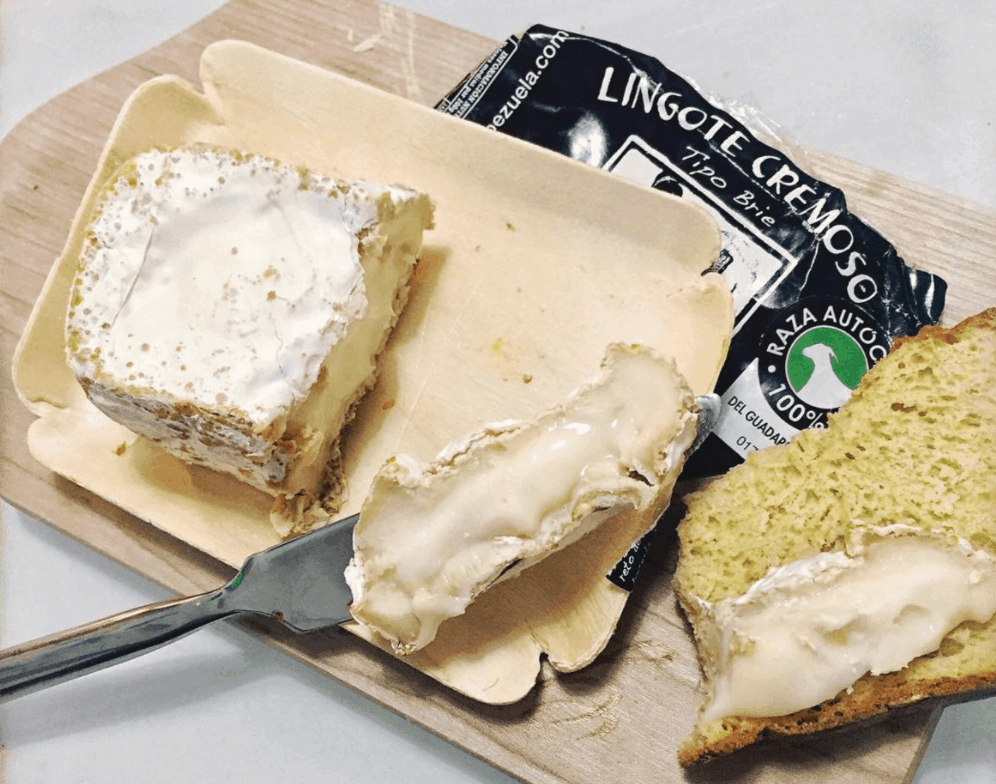

CREAMY INGOT

Madrid, Spain

New wave Brie-style cheese aged for a month-and-a-half that delivers herbal aromas and flavors of white pasta, acorn and thyme.

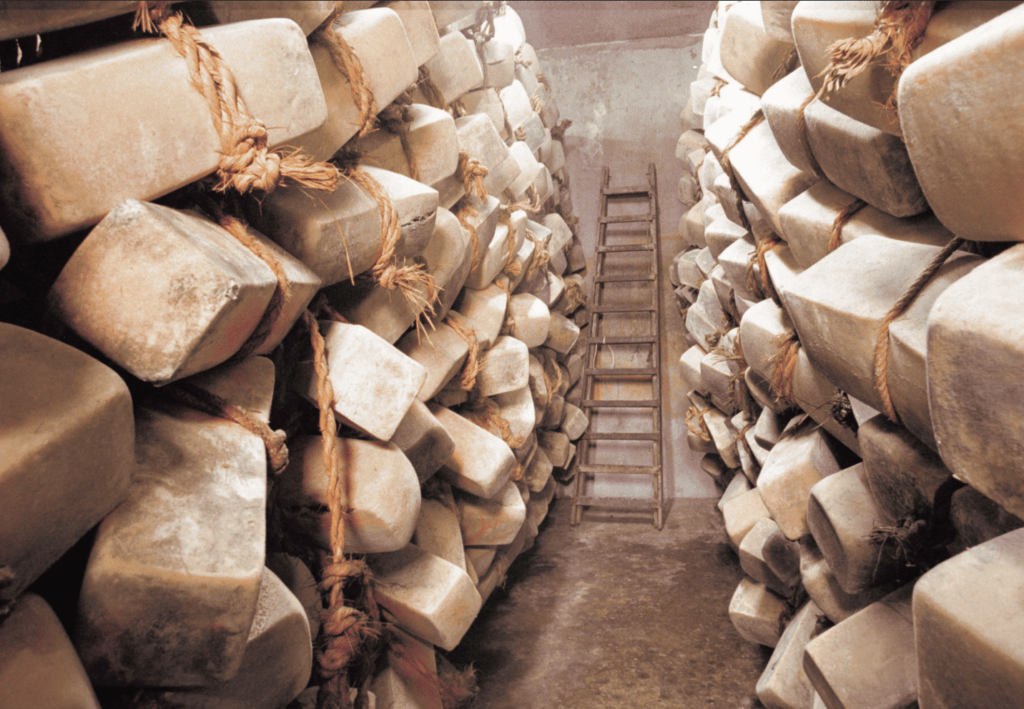

RAGUSANO PDO

Sicily, Italy

A straw-colored pasta filata cheese with a savory-sweet flavor offering extra spice as it ages.

SALERS TRADITION AOC

Auvergne, France

Semi-hard cow’s milk cheese which, at10 months of aging, offers floral notes contrasted by a sour tang.

VALENÇAY AOC

Berry, France

Covered in salted charcoal ash, this truncated goat’s milk cheese pyramid offers mouthfuls of creamy lemon and nut.

CROTTIN DE CHAVIGNOL AOC

Loire Valley, France

Goat’s milk cheese with a stark white interior which, when ripe, has a pungent aroma and an equally punchy flavor.

SWARTE TOER

Doetie’s Geiten

Jubbega, Netherlands

New wave Valençay-style that’s fresh and lactic when young, maturing to offer complex earth and floral flavors with a peppery finish.

BROUSSE DU ROVE AOC

Bas-Languedoc, France

A fresh cheese made from Rove goat’s milk that has a creamy texture and a sweet, milky flavor.

AMRAM

Milford, New Jersey

Made at Bobolink Dairy from unpasteurized cow’s milk, Amram has an ashy-grey rind after 60 days aging, and a sweet, grassy flavor with earthy notes.

BETHLEHEM

Bethlehem, Connecticut

Produced at the Abbey of Regina Laudis, this raw milk Saint-Nectaire–style has a rich, fruity aroma and nutty flavor.